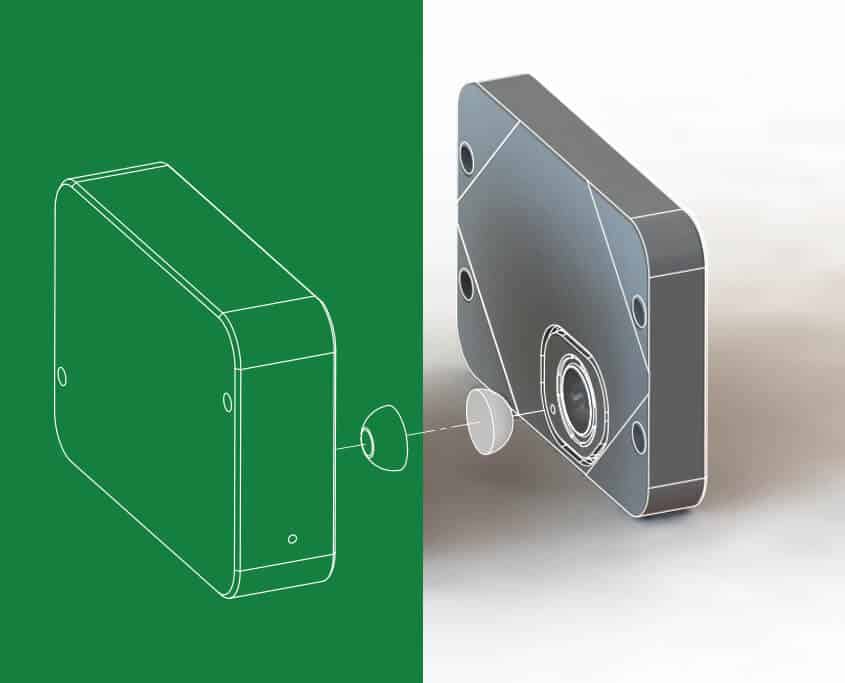

ENBI cases

LSR – Ball

Liquid Silicone Rubber Ball Together with UNIpace, The Polymer Application Center of...

Read MoreMono Spuitgieten – Medisch

BATTERY PACK Deze draagbare stroomvoorziening voor de medische wereld is een mooi...

Read MoreMono Spuitgieten – Automotive

Lift Bar Ook in de auto’s van onder andere Mercedes, BMW en...

Read MoreKUNSTSTOF

Ook in de auto’s van onder andere Mercedes, BMW en Audi zijn onderdelen te vinden die gemaakt zijn door Enbi Plastics & Silicones! Een voorbeeld is de lift bar, die het verbindingsstuk vormt tussen autoruiten en hun elektrische bediening.

Voor onze Duitse klant Vorwerk Elektrowerke, producent van premium huishoudelijke apparaten, maken we onder andere onderdelen voor hun slimme Thermomix-keukenmachines. Deze zijn zowel gericht op professionele keukens als op de consumentenmarkt. Een van de onderdelen die Enbi Plastics & Silicones maakt, is een positieschakelaar die ervoor zorgt dat de motor van de keukenmachine alleen wordt ingeschakeld als er een kom op is geplaatst.

Siliconen

Liquid Silicone Rubber (LSR) is een vloeibaar siliconen materiaal, wat verwerkt wordt door middel van een spuitgietproces. Dankzij de bijzondere materiaal- en verwerkingseigenschappen biedt LSR unieke vormgevings- en productiemogelijkheden voor Enbi Plastics & Silicones.

Liquid Silicone Rubber (LSR) is een steeds frequenter ingezette materiaalsoort voor spuitgietwerk bij Enbi Plastics & Silicones. Het is duurzaam, flexibel en extreem veelzijdig. Daarnaast is het ook nog eens kostenefficiënt.