Smart design.

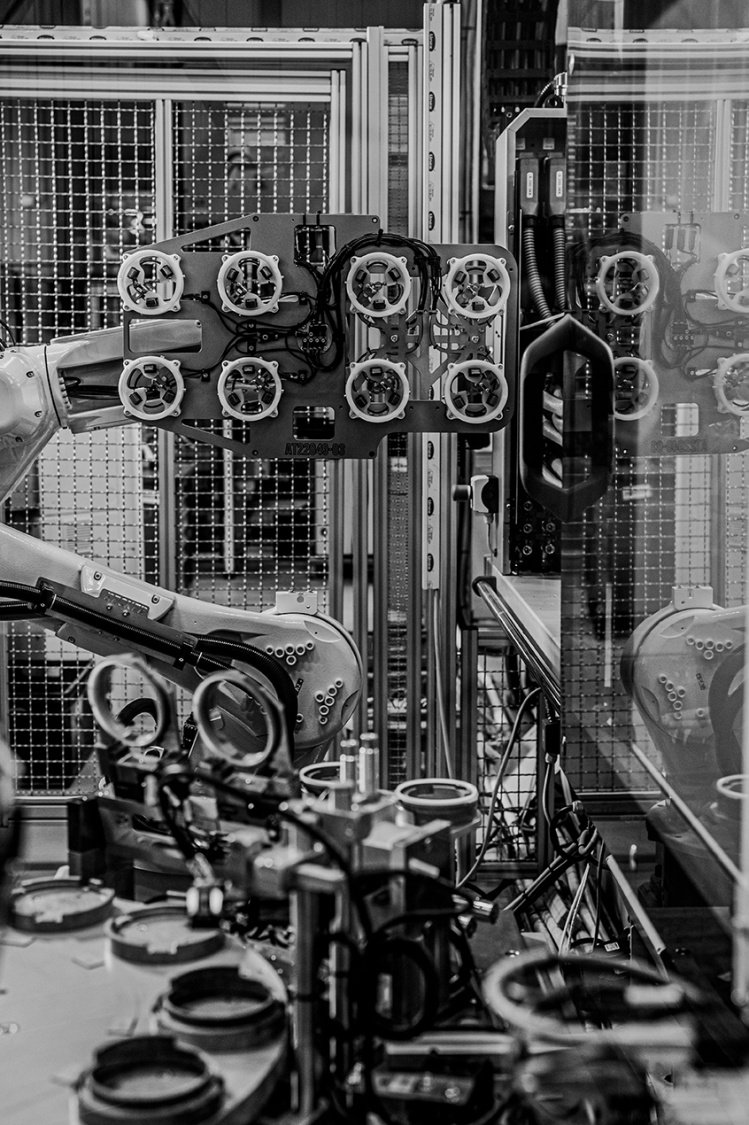

Intelligent automation.

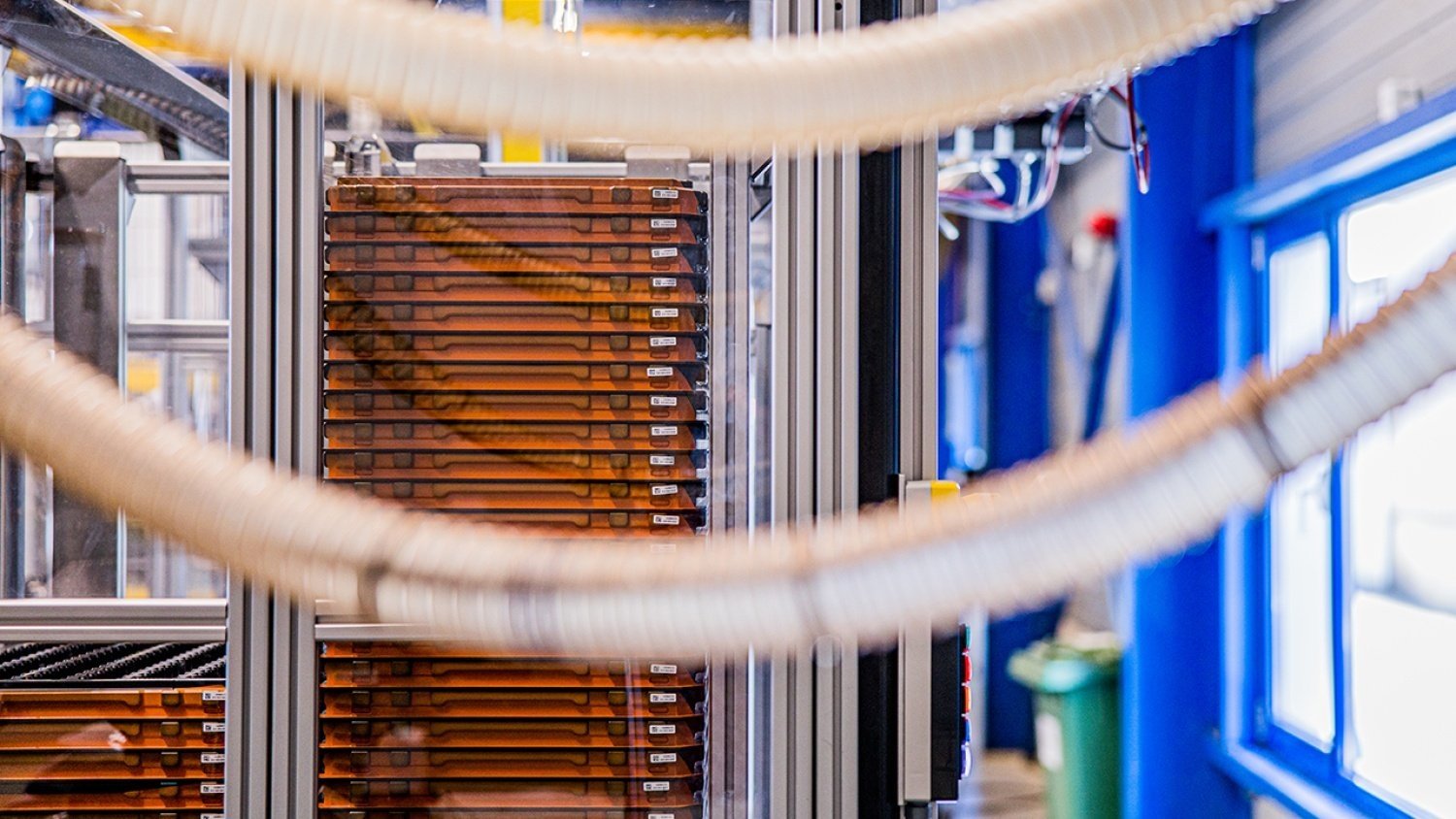

Automation is the key to making processes reliable, repeatable, and scalable. But it only works if you know exactly what you’re aiming for from the beginning. That’s why at ENBI, automation is woven into design and engineering right from day one.

By making the right decisions early, we create room for automation that works, technically sound, on time, and fully integrated into the solution. Read on to see how we approach it!

At ENBI, automation drives improvements in quality, throughput, scalability, and cost efficiency. It enables 24/7 production and automates repetitive tasks. - Pim, Project Engineer Automation