Translucent and seamlessly finished:

the production challenge of the Podcatcher Pro

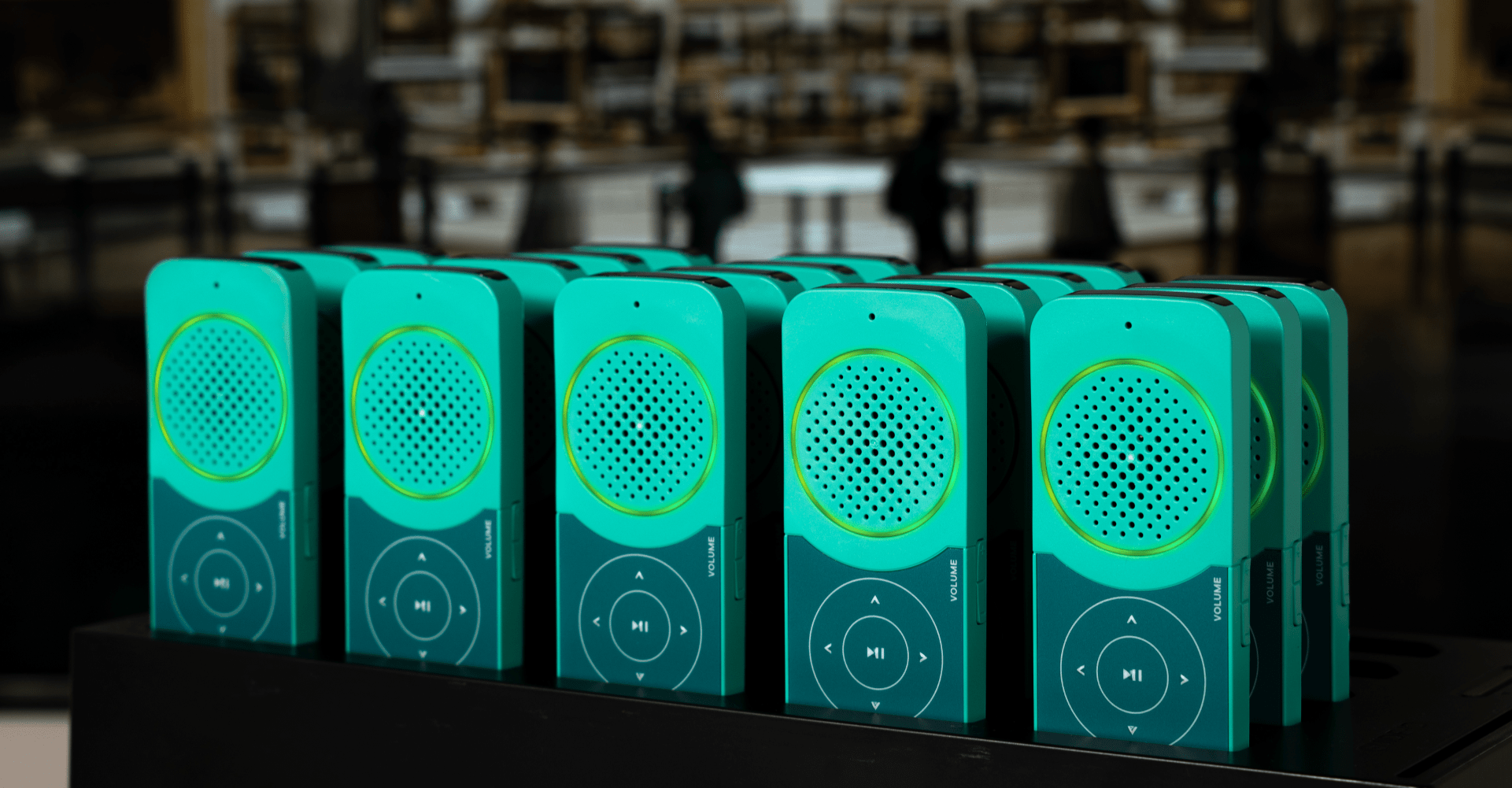

Guide ID is the driving force behind the Podcatcher Pro, “the world’s most advanced audio guide.” This smart guide brings culture, art, and nature to life, giving objects and spaces a voice and letting visitors expand their knowledge in an engaging way. With advanced audio technology and a compact design, visitors experience “the art of listening” in a unique way. Its stylish, user-friendly design is essential to that experience. ENBI Plastics & Silicones is responsible for producing this innovative product with its various components.

From concept to manufacturability: co-engineering in action

During the design phase, three product components were developed. The Podcatcher Pro consists of three components: a charging base, an identifier, and the guide. The guide is the most technically complex to produce at scale, due to its translucent ring. Initially, the guide was expected to be produced using a combination of LSR and plastic injection molding. Based on this, ENBI was approached by the design agency D’Andrea & Evers Design B.V.

UV bonding as the key solution

During the co-engineering phase, all requirements and functions were weighed against technical feasibility and product assembly. Limited tooling space, the need for a flawless finish, and the requirement for a seamless translucent ring led to abandoning LSR with molding. The solution was to use translucent PMMA, bonded to the other thermoplastic components with UV adhesive.

Material choice: balancing functionality and compatibility

Based on this approach, case studies were carried out, focusing on material selection and the bonding process, including automation. These case studies served as proof of concept, demonstrating the feasibility and effectiveness of the proposed approach. During this pre-engineering phase of the ENBI workflow, project engineer Tom ensured close collaboration between material suppliers, the ENBI project team, and the customer, Guide ID.

The Podcatcher Pro guide consists of three parts, a housing, lens cap, and light ring, each made from a different material. A key requirement for these plastic components is that the lens cap must use infrared-transmitting material for functionality, while the light ring must diffuse light for an optimal user experience. In addition to meeting functional requirements, all materials must also be compatible. The case studies showed which materials were most suitable for each component’s function and the product as a whole.

UV bonding: precision in automated processes

Beyond material choice, the bonding process is crucial to ensuring the light diffuses evenly. The adhesive must be applied continuously in ultra-small doses due to limited tooling space. Each guide involves two bonding steps:

- Bonding the light ring to the housing

- Bonding a sound-permeable plate into the light ring

Once both components are bonded, the guide passes through a UV tunnel for curing.

Because the dosage is so precise, 0.08 ml for both bonds, automation is essential for scalability. Pim, Project Engineer Automation, designed a process using a flexible cobot setup where people and machines work together seamlessly, ensuring consistency and quality.

An ENBI team member places the housing, the cobot applies the adhesive, and the team member installs the light ring. The adhesive is then reapplied, and the sound-permeable plate is inserted. The automation challenges Pim faced included:

- Following the exact geometry

- Accurate and consistent adhesive dosing

- Clamping and precise jig placement

- Training staff to correctly load products

From component to final product

Although ENBI wasn’t responsible for final assembly in this project, the team played a key role in delivering high-quality components, the charging base, identifier, and guide, that serve as the backbone of the innovative Podcatcher Pro. Thanks to technical expertise, close collaboration with material suppliers, and a sharp eye for detail, ENBI contributed to a product where technology and design merge seamlessly. This strong foundation enables the next steps to elevate the product to a premium standard.

Thank you, Guide ID, for the great collaboration and your openness to explore an alternative to the original concept. This way, we achieved the best possible result, together!