Designed for function.

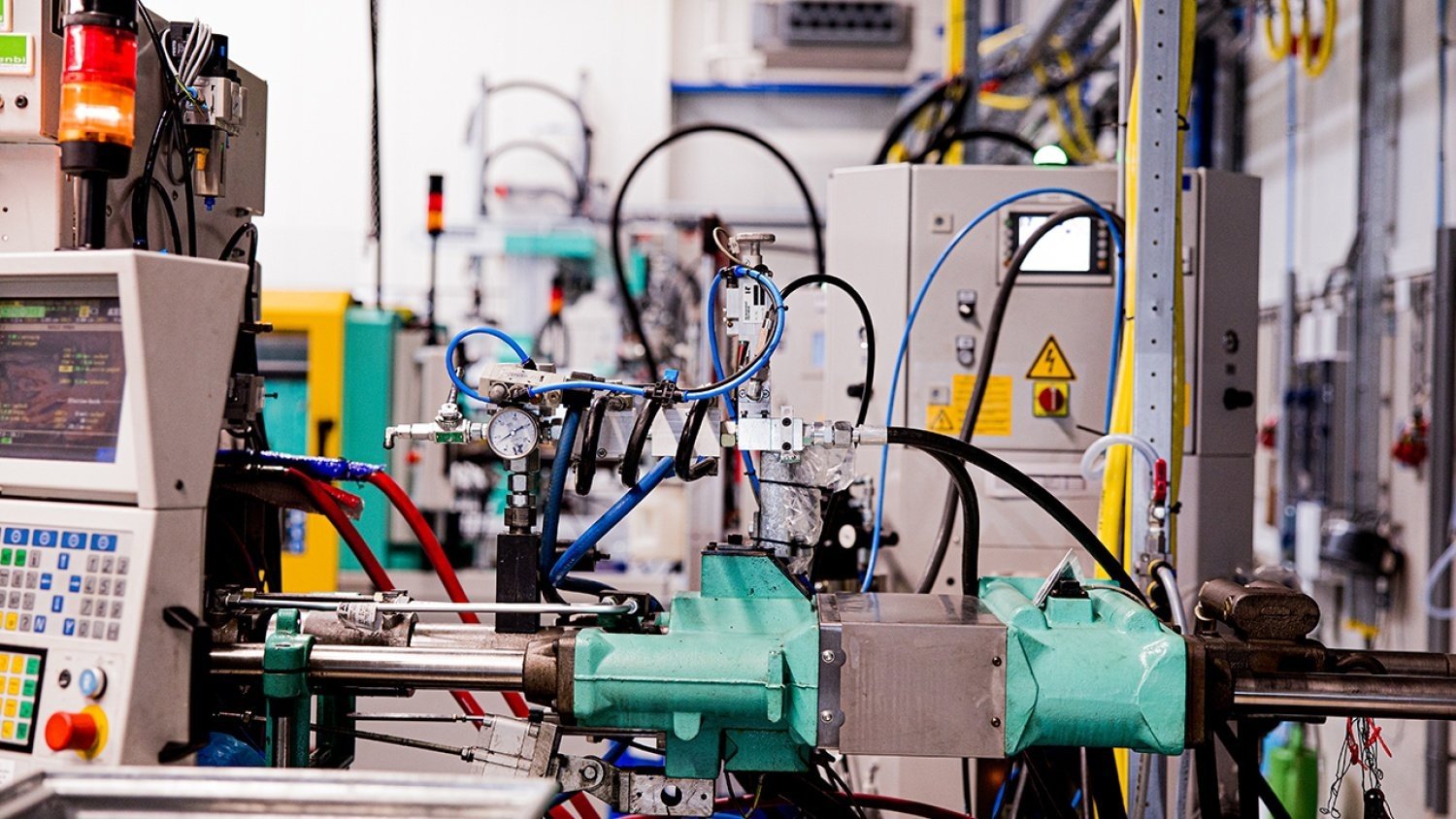

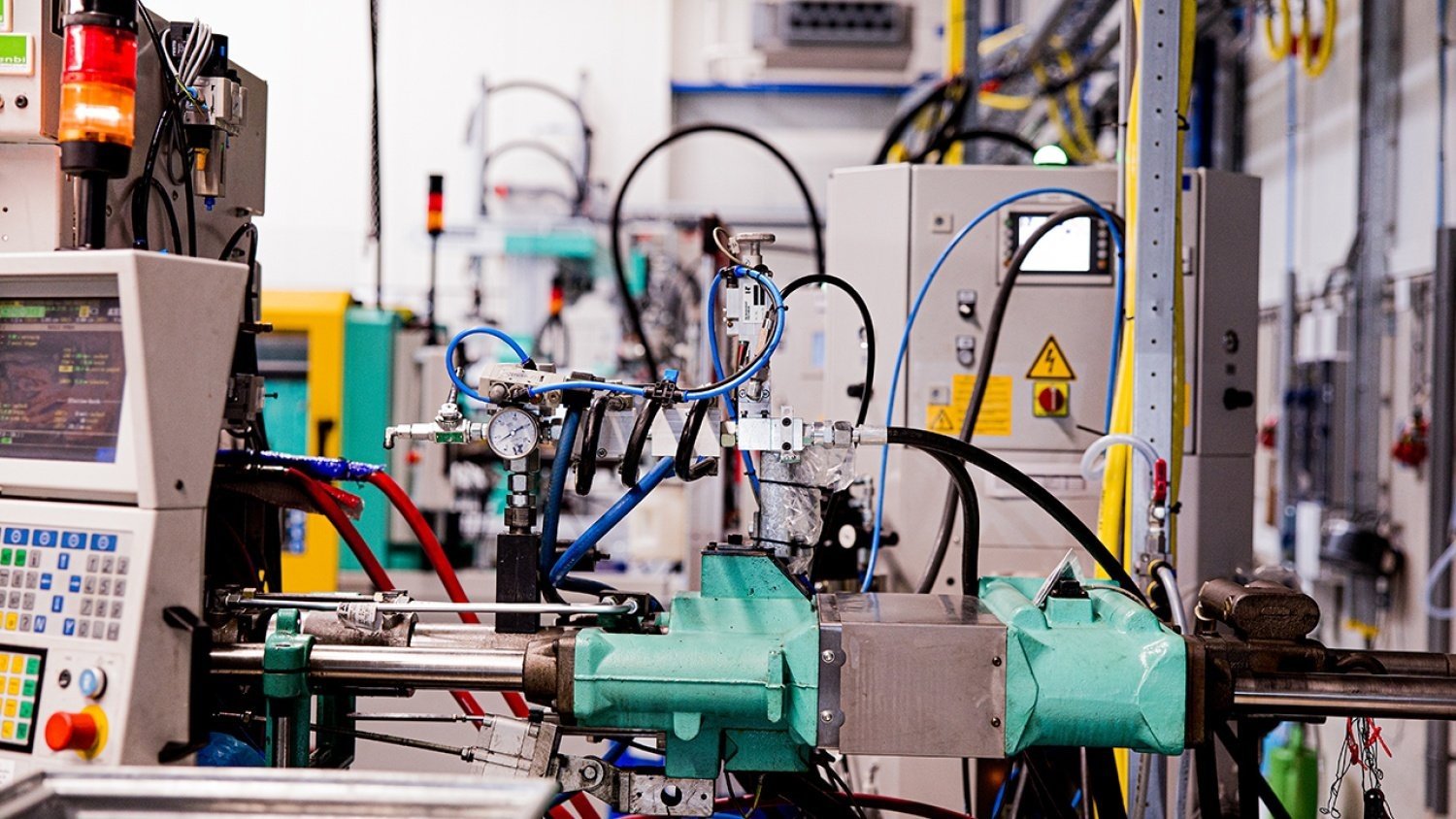

Shaped in silicone.

True success isn’t about how a part looks, it’s about how it performs. Absorbing pressure, sealing, guiding, damping, moving: in real-world conditions like skin contact, fluid exposure, temperature swings, or mechanical stress.

That’s why our process begins with function. Performance needs, such as pressure distribution, elasticity, temperature resistance, hygiene requirements: they define the design, the silicone grade, and the molding process.

Silicone molding is about more than just form. It’s about function, and making sure the application works technically and keeps performing under real-world conditions. - Roy, Sales & Engineering Manager