Getting started with LSR: What you need to know

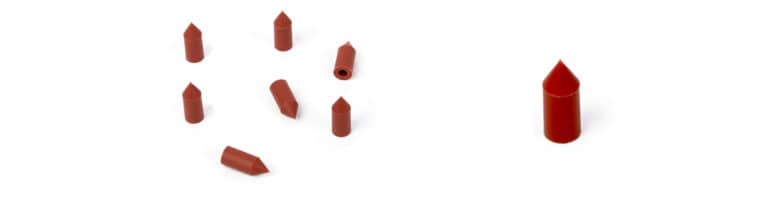

Liquid Silicone Rubber (LSR) is a material for injection moulding that is being used more and more by ENBI Plastics & Silicones. It is durable, flexible, and extremely versatile. Not to mention, it is also very cost efficient.

By means of this article, ENBI Plastics & Silicones aims to help you make the right decisions in terms of material type and which process composition best suits your project. Within just a few steps it’ll quickly become clear which choices are important when starting an LSR project. Do you want to know what LSR is exactly? Read more about the features and benefits of LSR in our previous article: “LSR offers unique design and production opportunity”.

IS LSR THE RIGHT MATERIAL FOR YOUR PROJECT?

The first step in product or project development is determining the right material. In terms of the production process at Enbi Plastics & Silicones, LSR comes with many benefits. These benefits are more extensively discussed in the previous article. These unique properties make LSR the best choice for a great variety of complex injection moulding projects.

LSR is a versatile material, which makes it suitable for a great variety of uses. For example, LSR can be used in the injection moulding of household appliances such as food processors. Additionally, thanks to its unique characteristics and benefits, LSR is also applicable in areas such as the automotive, agriculture, food, medical, and infant care sectors.

LSR is naturally resistant to degradation through chemicals, environment, or UV. The properties of the material remain stable, even with long-term exposure. LSR is also resistant to mold, mildew and other bacteria. In short, LSR is a versatile material and a smart choice for demanding applications.

Read more in our brochure…

Download the LSR brochure

Fill in your details and immediately download our free LSR leaflet with 7 inspiring short stories that will help you achieve success in developing products with LSR.

We will contact you in a few days, we would like to answer all your questions about LSR.

CUSTOM MADE COMPONENTS FOR YOUR BUSINESS

ENBI Plastics & Silicones produces custom designed,

high-quality LSR components.

From markets such as automotive and industrial

to the medical sector and household appliances.

Contact one of the specialists today

at ENBI Plastics & Silicones to explore the possibilities of

LSR in your industry!

Contact us

EMAIL [email protected]

Chamber of Commerce: 60055308

VAT: NL8537.48.627.B01

Ampereweg 15 | 6101 XE Echt | Netherlands